什么是熱成型鋼板車身件?

將硼鋼鋼板(初始強度為500~600MPa)加熱至奧氏體化狀態,快速轉移到模具中高速沖壓成形,在保證一定壓力的情況下,制件在模具本體中以大于27℃/s的冷卻速度進行淬火處理,保壓淬火一段時間,以獲得具有均勻馬氏體組織的超高強鋼零件(1300-1600Mpa)。

為何要使用熱成型鋼板車身件?

極高的材料強度及延展性。一般的高強度鋼板的抗拉強度在400-450MPa左右,而熱成形鋼材加熱前抗拉強度就已達到500-800 MPa,加熱成形后則提高至1300-1600 MPa。因此由熱成型鋼板制成的車身極大的提高了車身的抭碰撞能力和整體安全性,在碰撞中對車內人員會起到很好的保護作用。

有效的減輕整車重量,節約能耗。由于熱成型鋼板極高的材料強度,因此在設計時可以用一個熱成形零件代替多個普通鋼板的零件。這種零件具有厚度薄、重量輕、強度高,相比冷沖壓回彈性小,適合制造汽車A柱加強版、B柱加強版、地板部件、前端等,可為汽車提高安全性,減輕重量。

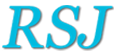

地板加強板使用了熱成型鋼板

側圍的A/B 立柱加強版使用了熱成型鋼板

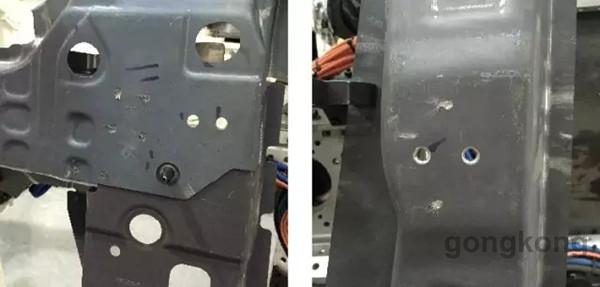

正如上述,熱成型鋼板有諸多優勢,故在汽車廠得到了越來越普遍的應用。但是,由于熱成型鋼板的電阻點焊的焊接性能非常特別,焊接參數帶非常窄,不同的廠家提供的熱成型鋼板的焊接電阻也差別大,進口的和國產的熱成型鋼板的電阻焊接性能也相差較大,這些都給汽車廠的零件的點焊工藝提出了嚴重的挑戰。汽車廠很難解決熱成型鋼板點焊時出現的大飛濺和大毛刺,于是,只能采用后續的毛刺打磨工序,來解決這個問題。設定打磨工序,不但污染環境,浪費人力物力,而且也整體降低了汽車零部件的生產效率。

熱成型鋼板點焊時,每個焊點都出現了嚴重的焊后毛刺

使用熱成型板中頻點焊技術 — 實現無飛濺,無毛刺的熱成型鋼板的點焊

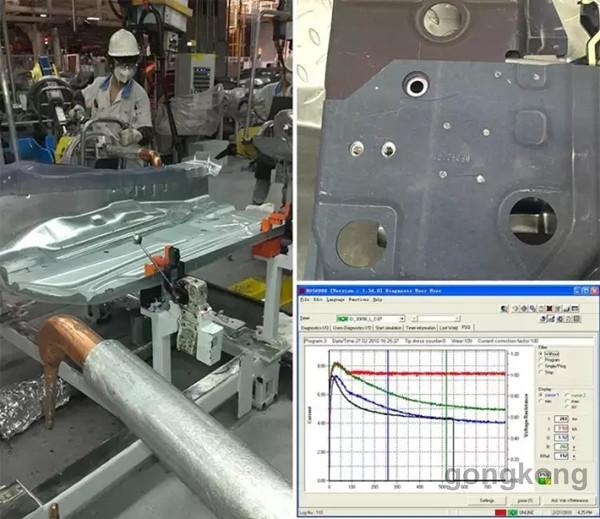

榮仕杰的中頻電阻點焊,使用的是動態電阻樣本曲線的可視化方式,可以輕松地得出各種熱成型鋼板的動態電阻特性曲線,并詳細分析出,不同類型,不同廠家提供的熱成型鋼板的動態電阻特性曲線,從而快速地得出各種熱成型鋼板合格的焊接規范及其動態電阻樣本曲線;在準確得到焊接熱成型鋼板合格的焊點(無飛濺,無毛刺)之后,立即將該動態電阻樣本曲線,下載到榮仕杰的焊接控制器里,接下來,打開自適應調節功能,這樣熱成型鋼板的焊點質量,就能完美閉環控制,而且沒有飛濺和毛刺,輕松徹底解決長期困擾汽車廠的焊接工藝難題。

目前,榮仕杰這種樣焊接熱成型鋼板技術,已經廣泛應用在國內大多數汽車工廠,好評如潮。無論是在手工焊接工位,還是機器人焊接工位,榮仕杰的中頻電阻點焊技術,都能巧奪天工般進行完美演繹。

英文版:

Rong Shijie hot forming plate spot welding technology.

Abstract: Rongshijie's IF adaptive resistance spot welding uses a visualization method of dynamic resistance sample curve, which can easily obtain the dynamic resistance characteristic curves

of various thermoformed steel sheets, and analyze in detail, different types and different manufacturers. The dynamic resistance characteristic curve of the thermoformed steel sheet is provided, so that the qualified welding specifications of various

thermoformed steel sheets and the dynamic resistance sample curve thereof can be quickly obtained; the qualified solder joints of the welded thermoformed steel sheet can be accurately obtained (no splash, no burr) Immediately, the dynamic resistance

sample curve is downloaded to Bosch's welding controller. Next, the adaptive adjustment function is turned on, so that the quality of the welded joint of the thermoformed steel plate can be perfectly closed-loop controlled without splashes and burrs.

Thoroughly solve the welding process problems that have long plagued automobile factories.

What is a thermoformed steel body part?

The boron steel plate (initial strength is 500~600MPa) is heated to the austenitizing state, and is quickly transferred to the high-speed stamping forming in the mold. Under the condition of ensuring a certain pressure, the workpiece is more

than 27 ° C / s in the mold body. The cooling rate is quenched and quenched for a period of time to obtain ultra-high strength steel parts (1300-1600 MPa) with uniform martensite structure.

Why use thermoformed steel body parts?

Extremely high material strength and ductility. The tensile strength of a general high-strength steel sheet is about 400-450 MPa, and the tensile strength of the hot-formed steel before heating is 500-800 MPa, and is increased to 1300-1600

MPa after heat forming. Therefore, the body made of thermoformed steel plate greatly improves the collision capability and overall safety of the vehicle body, and plays a good role in protecting the inside of the vehicle during the collision.

Effectively reduce the weight of the vehicle and save energy. Due to the extremely high material strength of thermoformed steel sheets, it is possible to replace a number of common steel sheet parts with a hot formed part during design. This

kind of parts has thin thickness, light weight and high strength. It is suitable for the manufacture of automobile A-pillar reinforced version, B-pillar reinforced version, floor parts and front end, etc., which can improve safety and reduce weight

for automobiles.

Floor reinforced panels use thermoformed steel sheets

Floor reinforced panels use thermoformed steel sheets

Side-walled A/B column reinforcement uses thermoformed steel

Side-walled A/B column reinforcement uses thermoformed steel

As mentioned above, thermoformed steel sheets have many advantages and are therefore becoming more and more popular in automotive plants. However, due to the special welding performance of the resistance spot welding of the thermoformed steel

sheet, the welding parameter band is very narrow, and the welding resistance of the thermoformed steel sheet provided by different manufacturers is also large, and the resistance welding properties of the imported and domestic thermoformed steel sheets

are also The large difference is a serious challenge to the spot welding process of the parts of the automaker. It is difficult for automakers to solve the large splashes and large burrs that occur during spot welding of hot-formed steel sheets. Therefore,

only the subsequent burr grinding process can be used to solve this problem. Setting the grinding process not only pollutes the environment, but also wastes manpower and material resources, and also reduces the overall production efficiency of auto

parts.

Severe post-weld burrs at each solder joint during spot welding of hot-formed steel sheets

Severe post-weld burrs at each solder joint during spot welding of hot-formed steel sheets

Use Rongshijie IF welding technology - spot welding of sputter-free, burr-free thermoformed steel sheets

Rong Shijie's medium frequency resistance spot welding uses a visualization method of dynamic resistance sample curve. It can easily obtain the dynamic resistance characteristic curves of various thermoformed steel sheets, and analyze in detail

the different types and different manufacturers provide thermoforming. The dynamic resistance characteristic curve of the steel plate, so as to quickly obtain the qualified welding specifications of various thermoformed steel sheets and their dynamic

resistance sample curves; after accurately obtaining the qualified solder joints of the welded thermoformed steel sheets (no splash, no burr), immediately The dynamic resistance sample curve is downloaded to Bosch's welding controller. Next, the adaptive

adjustment function is turned on, so that the solder joint quality of the thermoformed steel plate can be perfectly closed-loop controlled, and there is no splash and burr, and the long-term trouble is easily solved. The welding process of the car

factory.

At present, Rongshijie's sample curve thermoformed plate welded thermoformed steel plate technology has been widely used in most domestic automobile factories, and received rave reviews. Whether in the manual welding station or the robotic

welding station, Rongshijie's medium-frequency resistance spot welding technology can be perfectly interpreted.

Bosch Rexroth spot welding of thermoformed steel in manual work